How to Reverse Crystallisation in Epoxy Resins!

Preventing Crystallisation in Epoxy Resin

Crystallisation is an inevitability during the colder months - and is one of the most common queries we get regarding Vista Resin through the winter period. Despite first appearances, all is not lost with crystallised resin, and it is a fairly simple process to reverse.

What is Crystallised Resin?

Crystallisation affects the Part A of a two-part epoxy system. If your Part A is almost completely solid, cloudy, extra thick, or has small white flakes in it, then crystallisation has occurred to some degree. Resin is a super-cooled liquid, meaning that it won’t freeze at standard freezing temperatures, crystals form at these lower temperatures, hence the appearance of the resin.

Crystallisation is caused by temperature fluctuations, specifically prolonged exposure to cold temperatures. Often overnight in a couriers’ warehouse is enough to cause this, as well as storage in a colder area such as a garage or shed.

How to Reverse Crystallisation

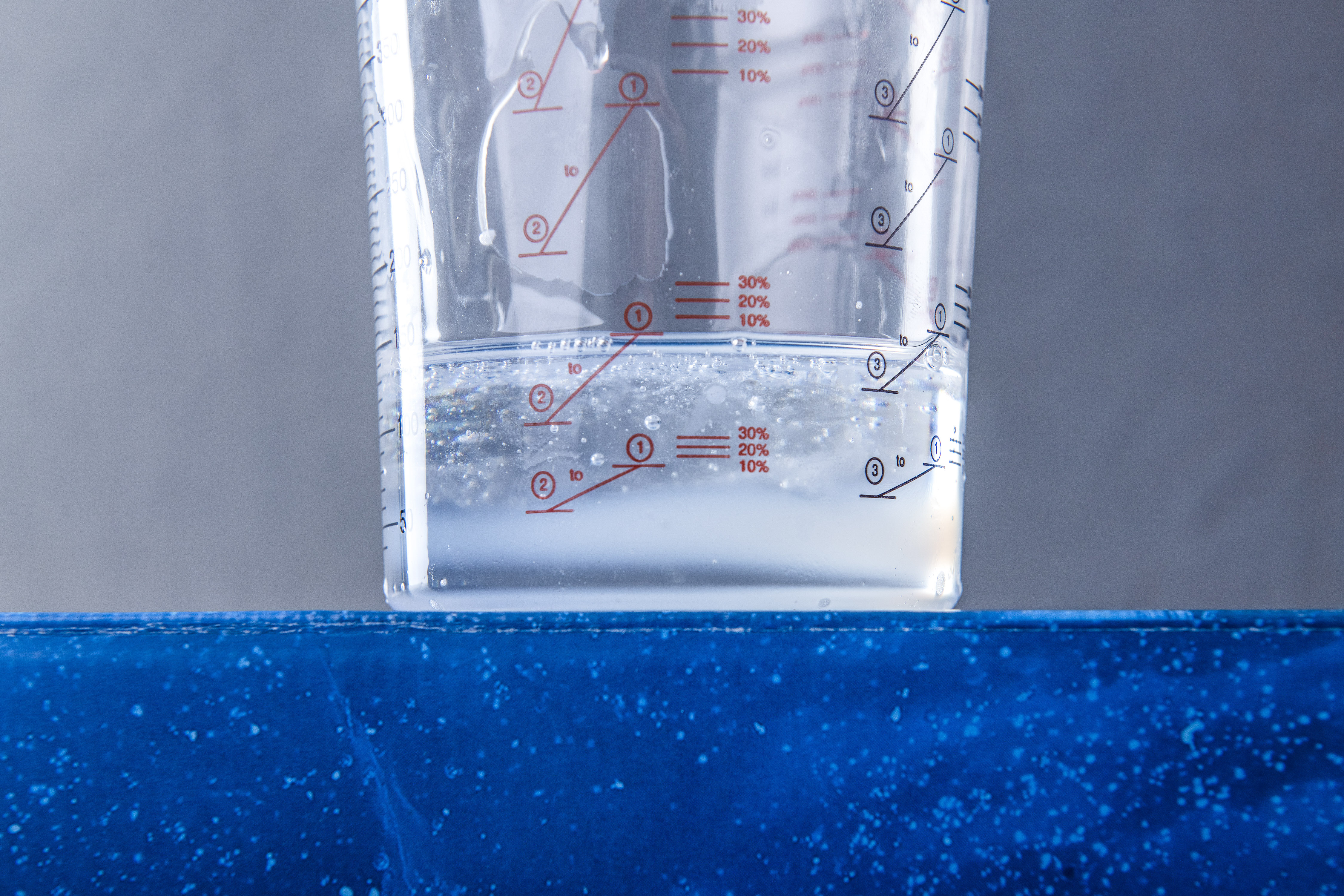

Crystallisation can be reversed by applying heat. The most effective method is to use hot water to “bathe” the Part A container in. If your resin is pourable, then you can measure out the required amount of Part A into a plastic cup, and then place the cup in hot water – taking care not to splash water into the cup, and of course not allowing the cup to tip over. Generally, a cup of 200g of resin will take around 10-15 minutes to fully de-crystallise this way. In severe cases it may be necessary to put the full Part A in a bath of hot water to de-crystallise over time, this may take up to an hour or more depending on the resin and quantity. For larger quantities such as this the hot water will need to be topped up over time as it cools.

Further Advice

Once the resin appears fully de-crystallised, check for any residual cloudiness or white flakes, if any remain, place the Part A back in the hot bath for a while longer. When the resin is fully clear, allow to cool back to near room temperature before mixing with the Part B. It may be necessary to stir the Part A, and make sure there is no hot patch remaining in the centre of the resin which would raise the temperature of the whole mix. Don’t forget epoxy cures with an exothermic reaction, and mixing Part A and B when Part A is too hot could lead to a flash cure.

Remember that crystallisation can occur with any epoxy - and is more common in low viscosity resins. As such, it is an occupational hazard of the hobby. Storing your resin at a reasonable temperature of 22°C and above, keeping your equipment and lids clean and wiped down to avoid contamination will help reduce the potential for crystallisation.

Don’t forget to check out our YouTube video for a visual guide to de-crystallising your epoxy.

Hopefully this has answered your questions regarding crystallisation in epoxy resin, thanks for reading.